In the highly competitive and complex field of construction, the building envelope plays an essential role far beyond its aesthetic value.

In 2025, building and maintaining modern building envelopes requires a strategic approach rooted in innovative materials and expert design.

In this article, we’ll give advice to owners, developers, architects, and facility managers who rely on trusted engineering partners to safeguard their investments through superior building envelope solutions.

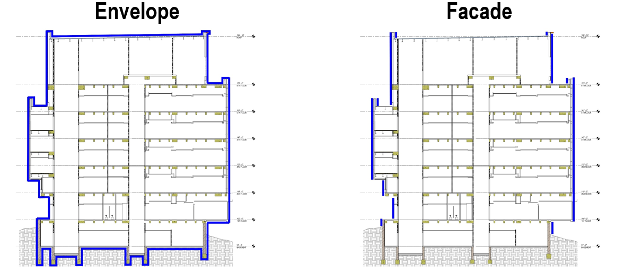

Your building envelope encompasses roofs, walls, windows, doors, and foundational elements. The envelope controls heat flow, moisture transfer, air infiltration, and structural loads, making it fundamental to a building’s overall performance.

A poorly designed or constructed building envelope can lead to serious issues such as water intrusion, mold growth, energy inefficiency, and premature material failure. These problems jeopardize comfort, safety, and long-term asset value. On the other hand, a well-engineered envelope enhances energy savings, indoor air quality, durability, and resilience.

Key Structural Engineering Considerations

At the core of effective building envelope design lies the structural engineer’s expertise in managing loads, materials, and connections. The structural engineering team ensures it withstands all imposed stresses over its lifespan.

Critical considerations include:

- Load Resistance: The building envelope must resist wind pressures, seismic activity, thermal-induced movement, and settlement without compromising structural integrity.

- Material Compatibility: Selecting materials that work well together to prevent issues such as differential movement or corrosion at interfaces.

- Connection Detailing: Designing robust, flexible joints and anchor systems that accommodate thermal expansion, moisture movement, and structural deflections.

- Moisture and Air Management: Proper integration of waterproof membranes, air barriers, and drainage planes to prevent water infiltration and condensation, reducing risks to structural components.

- Durability and Maintenance: Strategies to extend service life, ease inspection, and simplify repairs, thereby reducing lifecycle costs.

Innovations in 2025

Today’s structural engineering approaches can elevate building envelope performance:

- High-Performance Composite Panels: Lightweight, corrosion-resistant panels with integrated insulation streamline assemblies while meeting stringent load and thermal requirements.

- Continuous Insulation and Thermal Breaks: Minimizing heat transfer through uninterrupted insulation layers reduces energy waste and mitigates condensation risks.

- Digital Modeling and BIM Integration: Using 3D building information modeling for clash detection, constructability reviews, and precise fabrication.

- Prefabrication and Modular Facades: Off-site fabrication improves quality control and reduces job-site errors related to envelope assembly.

- Advanced Sealant and Membrane Technologies: Improved elasticity, adhesion, and durability enhance weatherproofing and airtightness.

Why Choose an Expert Structural Engineering Partner?

Successful building envelope projects demand an approach where structural engineers act as trusted advisors at every phase. From conceptual design to construction administration, our team provides:

- Comprehensive Structural Analysis

- Material Selection Guidance

- Connection and Anchorage Design

- Constructability Reviews

- Quality Assurance and Field Support

The building envelope is a long-term investment that directly impacts operational costs, occupant well-being, and property resale value. By integrating structural engineering best practices, owners and developers gain assurance against premature failures and costly repairs.

Contact us today to discuss how our building envelope expertise can help realize your vision while ensuring enduring structural integrity and value.